What is a Furnace Inducer Motor?

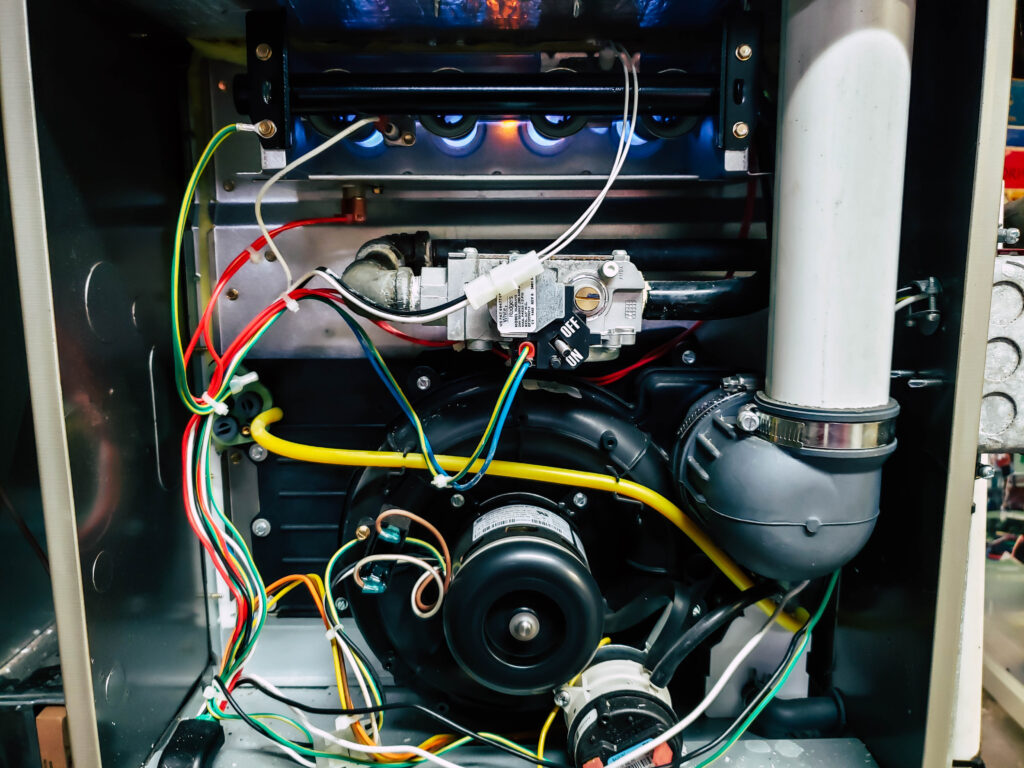

A furnace inducer motor, also known as a draft inducer motor, is a crucial component in modern, high-efficiency gas furnaces. Despite its small size, it plays a vital role in ensuring safe and efficient furnace operation.

Table of Contents

Function of a Furnace Inducer Motor

The furnace inducer motor performs two essential functions:

- Safe Removal of Exhaust Fumes: It creates a negative pressure within the furnace chamber. This suction effect draws combustion gases produced during the heating process out of the furnace and vents them safely through the flue pipe. This prevents harmful fumes from accumulating inside your home.

- Optimum Combustion Efficiency: The inducer motor also helps draw fresh air into the furnace. This steady flow of oxygen ensures efficient fuel burning, maximizing heat production and reducing energy consumption.

The inducer motor is typically located near the base of the furnace, close to the flue pipe. It consists of a small electric motor connected to a fan blade that pulls air through the system.

Role of the Inducer Motor in the Heating Cycle

Here’s a break down the sequence of events that occur during a heating cycle, highlighting the inducer motor’s contribution at each stage:

1) Pre-purge (30-60 seconds)

When the thermostat signals for heat, the first component to activate is the inducer motor. It runs for about 30-60 seconds, acting like a tiny vacuum cleaner. This pre-purge removes any lingering gases, such as residual combustion products, from the heat exchanger and flue pipes.

2) Creating Negative Pressure

As the inducer motor’s fan spins, it pulls fresh air into the combustion chamber. This creates a slight vacuum, typically measured in inches of water column (often -0.5 to -1.5). This negative pressure is essential for proper air intake and efficient fuel burning.

3) Airflow Verification

A pressure switch, another safety component within the furnace, monitors the airflow created by the inducer motor. Only if the pressure switch detects sufficient airflow will it allow the ignition sequence to proceed. This ensures there’s proper ventilation before igniting the gas, preventing potential buildup of harmful gases.

4) Supporting Combustion

Once the pressure switch confirms adequate airflow, the gas valve opens, and the igniter sparks to light the burners. The inducer motor continues to run throughout the heating cycle. It serves two crucial purposes at this stage:

- Supplying Oxygen: The continuous flow of air from the inducer motor provides the necessary oxygen for efficient fuel combustion. Without sufficient oxygen, the burners wouldn’t burn cleanly, leading to incomplete combustion and potential issues like soot buildup and reduced heating efficiency.

- Removing Exhaust Gases: The inducer motor also acts as an exhaust fan, drawing out the combustion gases produced during the heating process. These gases are safely expelled through the flue system and vented outside your home. This ensures proper ventilation and prevents the buildup of harmful gases like carbon monoxide inside your living space.

5) Post-purge (Short duration):

Even after the heating cycle finishes, the inducer motor runs for a short additional time. This post-purge operation ensures that all remaining combustion gases are completely expelled from the furnace and flue system before the furnace shuts down entirely.

By following these steps, the inducer motor ensures a safe and efficient heating process. It removes lingering gases, creates proper airflow for combustion, and vents out harmful byproducts, keeping your home warm and comfortable without compromising safety.

How to Tell if Your Furnace Inducer Motor is Failing

Furnaces are built to last, but inducer motors can wear down over time. Here are some signs to watch out for:

- Unusual noises: Grinding, rattling, or clicking sounds coming from your furnace could indicate problems with the motor’s bearings, fan blades, or other internal components.

- Frequent shutdowns: A failing motor might struggle to maintain airflow, causing the furnace to overheat and shut down as a safety precaution.

- Error codes: Modern furnaces often display error codes related to air pressure, draft, or ventilation issues, which might point to a faulty inducer motor.

- Visible damage: Look for debris buildup around the motor or fan, stuck blades, or burn marks on the casing, which could indicate physical damage.

What Causes a Furnace Inducer Motor to Go Bad?

Several factors can contribute to a failing inducer motor:

- Normal wear and tear: Over time, constant use can wear down the motor’s bearings and shafts, leading to decreased performance and eventual failure.

- Overheating: Frequent short-cycling or a clogged flue can cause the motor to work harder and overheat, leading to damage.

- Electrical issues: Problems with the control board, wiring, or capacitor can affect power supply to the motor, causing it to malfunction.

- Moisture damage: Exposure to moisture can corrode electrical components and shorten the motor’s lifespan.

- Improper installation: Incorrect installation or mismatched furnace size can put excessive strain on the motor, leading to premature failure.

- Lack of maintenance: Neglecting regular maintenance allows dirt and grime to accumulate. This increases friction within the motor, accelerating wear and tear and potentially causing it to seize up completely.

How Much Does it Cost to Replace a Furnace Inducer Motor?

Replacing a furnace inducer motor typically costs between $400 and $1,100, with an average of $700. This includes both parts and labor. Here’s a breakdown of the cost factors:

Motor type and brand

Original equipment manufacturer (OEM) motors are more expensive than generic replacements. Energy-efficient ECM motors also cost more than standard PSC motors.

Furnace size and efficiency

Larger and high-efficiency furnaces require more powerful motors, increasing the cost.

Labor costs

These vary by region but typically range from $75 to $150 per hour. Complexity of the installation and accessibility of the furnace also affect labor costs.

Additional parts

Replacing related components like pressure switches can add to the overall cost.

Warranty coverage

If your furnace is under warranty, you might only pay for labor.

Maintenance for a Furnace Inducer Motor

While you might be comfortable tackling some basic furnace maintenance tasks like changing air filters, replacing an inducer motor is a job best left to a qualified HVAC technician. Here’s why:

Specialized Knowledge and Tools

Inducer motors are located within the furnace cabinet and require specific knowledge to access and replace safely. They are connected to electrical wiring, venting systems, and other furnace components.

An HVAC professional will have the expertise to diagnose the problem accurately, ensure proper removal and installation of the new motor, and verify all connections are secure and functioning correctly.

Safety Concerns

Furnace repairs involve dealing with gas and electricity, which can be dangerous if handled incorrectly. Disassembling the furnace to access the inducer motor exposes you to potential hazards like gas leaks or electrical shock. A qualified technician will have the safety gear and training to work on your furnace safely and minimize any risks.

Warranty Considerations

Many furnace manufacturers offer warranties on their products. Attempting DIY repairs on the inducer motor, especially if it involves electrical work, could void your warranty. This means you’ll be responsible for the full cost of repairs if something goes wrong after your tinkering.

Avoiding Future Problems

An HVAC expert can not only replace the inducer motor but also identify the underlying cause of its failure. This could be clogged flue pipes, faulty control boards, or improper furnace sizing. Addressing these root causes can help prevent future problems and extend the lifespan of your entire furnace system.

In addition to the above, consider the time and frustration you might save by calling a professional. They can diagnose the problem quickly, get the right parts, and complete the repair efficiently, minimizing downtime for your heating system.

Conclusion

The furnace inducer motor plays a vital role in keeping your furnace operating safely and efficiently. By understanding its function and the signs of potential trouble, you can ensure a warm and comfortable home throughout the winter months. Regular maintenance can extend the lifespan of your inducer motor, saving you money on repairs and replacements down the road.

However, If you suspect any issues or have concerns about your furnace’s performance, don’t hesitate to contact a trusted HVAC professional. By leveraging their expertise, an HVAC professional can ensure the entire repair process is completed safely and efficiently, keeping your furnace running smoothly and your home warm and comfortable.

Request Service

Get started by filling out a request form or by giving us a call.

FAQs

What happens when a furnace inducer motor goes out?

A malfunctioning inducer motor can prevent your furnace from venting exhaust fumes properly, leading to potential safety risks and reduced efficiency. It can also cause the furnace to fail to ignite or shut down unexpectedly.

Can you run a furnace without an inducer motor?

No, it’s not safe to operate a furnace without a functioning inducer motor. The motor is essential for venting harmful exhaust gases and ensuring proper combustion. Attempting to run the furnace without it can lead to carbon monoxide poisoning and other safety hazards.

Check Out Additional HVAC Resources

- Guide to HVAC Hard Start Kits

- Guide to Furnace Installation

- Ductless Mini Splits vs Central AC

- MERV 8 vs Merv 11 vs Merv 13: Which is Best?

- How to Clean a Clogged AC Drain Line

Sources

Anna has over six years of experience in the home services and journalism industries and serves as the Content Manager at MyHomePros.com, specializing in making complex home improvement topics like HVAC, roofing, and plumbing accessible to all. With a bachelor’s degree in journalism from Auburn University, she excels in crafting localized, comprehensive guides that cater to homeowners’ unique needs. Living on both coasts of the United States has equipped her with a distinctive perspective, fueling her passion for turning any house into a cherished home through informed, personalized decision-making.

888-524-2244

888-524-2244